THE RIDDELL SPEEDFLEX PRECISION DIAMOND HELMET DELIVERS NEXT GENERATION INNOVATION WITH NEW DIGITALLY MANUFACTURED FOOTBALL HELMET LINER.

DES PLAINES, ILL. AND REDWOOD CITY, CA. Riddell and Carbon have partnered to bring customized, digital design innovation to head protection through Riddell’s new Diamond helmet platform. Powered by Carbon, the new platform features a 3D printed lattice liner that is digitally manufactured using Carbon’s proprietary Digital Light Synthesis™ (DLS™) technology. The technology is initially available in the Riddell SpeedFlex Precision Diamond helmet model, which features Riddell’s Precision- Fit head scanning and helmet fitting process. The result is next-generation head protection for today’s athletes–a customized, 3D printed helmet liner precisely contoured to the athlete’s head.

“Riddell is known for head protection leadership. Our partnership with Carbon, Silicon Valley’s leading digital manufacturer, reinforces our commitment to advancing on-field protection for football players,” said Riddell Senior Vice President of Research and Product Development, Thad Ide. “As the first to use digital manufacturing in football helmets, Riddell continues our industry leadership by embracing promising new technologies and advancing our innovation roadmap today and into the future.”

“At Carbon, we believe in using the power of technology to advance innovation. Our platform enables companies like Riddell to make products that were never thought possible,” said CEO and Co-founder Dr. Joseph DeSimone. “With this partnership, Riddell becomes one of the largest users of 3D printers in the world. We are proud to be at the forefront of digital manufacturing of protective equipment.”

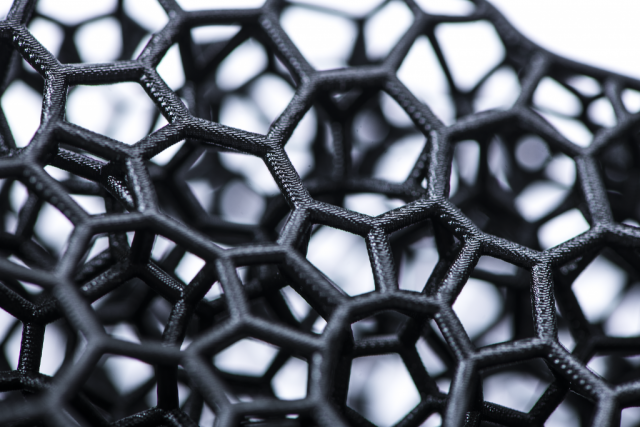

The core technology uses a custom designed, highly damping elastomer from Carbon, in the form of a lattice structure to create the helmet liner. The Carbon Lattice Engine leverages physical simulation and optimization techniques to tune structures to further manage both linear and rotational impact energies. Each helmet is made up of more than 140,000 individual struts, carefully orchestrated into patterns for attenuating impact forces while providing excellent comfort and fit. The result is a Carbon DLS-printed, custom fit, impact absorbing helmet liner designed to advance the state-of-the-art in head protection. Riddell’s proprietary database of over 5 million impacts captured by Riddell’s smart helmet technology will allow for custom and individualized tuning of lattice structures in the future.

Carbon’s recent breakthroughs in software, hardware and materials make the Diamond platform possible. The very latest advancements in Carbon’s platform include the new L1 printer and custom resin material. The L1, also being unveiled by Carbon today, is specially designed and built to produce at scale. The custom resin used to print the lattice structures in the Diamond liners was designed specifically to meet Riddell’s rigorous performance requirements.

“As someone who’s spent thousands of hours watching film, I know that no two players play the same way,” said Riddell Strategic Advisor and Brand Ambassador Peyton Manning. “They all have different styles and tendencies on the field, which is another key benefit to Riddell’s Diamond Technology. With the SpeedFlex Precision Diamond, players are not only experiencing the latest in head protection, they can also dictate where the helmet is positioned to improve sightlines and maximize field vision.”

Riddell SpeedFlex Precision Diamond helmets were used by select players on most NFL teams during the 2018 season and will be commercially available on a limited basis at the elite level starting in 2019.

For more information about the Riddell Diamond Technology, please visit www.riddell.com/diamond and www.Carbon3d.com/ProtectItAll and join in on the conversation at #PROTECTITALL.

ABOUT RIDDELL

Riddell is a premier designer and developer of football helmets, protective sports equipment, head impact monitoring technologies, apparel and related accessories. A recognized leader in helmet technology and innovation, Riddell is the leading manufacturer of football helmets and shoulder pads, and a top provider of reconditioning services (cleaning, repairing, repainting and recertifying existing equipment). For more information, visit our website at http://www.riddell.com, like the Riddell Facebook page, or follow Riddell on Instagram and Twitter @RiddellSports.

ABOUT CARBON

Carbon’s mission is to reinvent how polymer products are designed, engineered, manufactured, and delivered, towards a digital and sustainable future. Based in Silicon Valley, Carbon brings together innovations in software, hardware, and molecular science to deliver industry-leading digital manufacturing solutions. With Carbon’s ground-breaking Digital Light Synthesis™ technology and broad family of programmable liquid resins, manufacturers can unlock new business opportunities such as mass customization, on-demand inventory, and previously impossible product designs. The Carbon Platform allows customers to build uniquely differentiated products while reducing waste and speeding time to market. To learn more, visit www.Carbon3d.com, like the Carbon Facebook page, or follow Carbon on Instagram and Twitter at @Carbon.

FOR MORE INFORMATION, PLEASE CONTACT:

Erin Griffin

Vice President of Marketing & Communications, Riddell

(P) 224.585.5231

Brandan Orsatti

Vice President, Cohn & Wolfe for Riddell

(P) 212.798.9724

Iska Hain Saric

Head of Strategic Communications, Carbon

(P) 267.243.9197

Photos and Press Release: Carbon