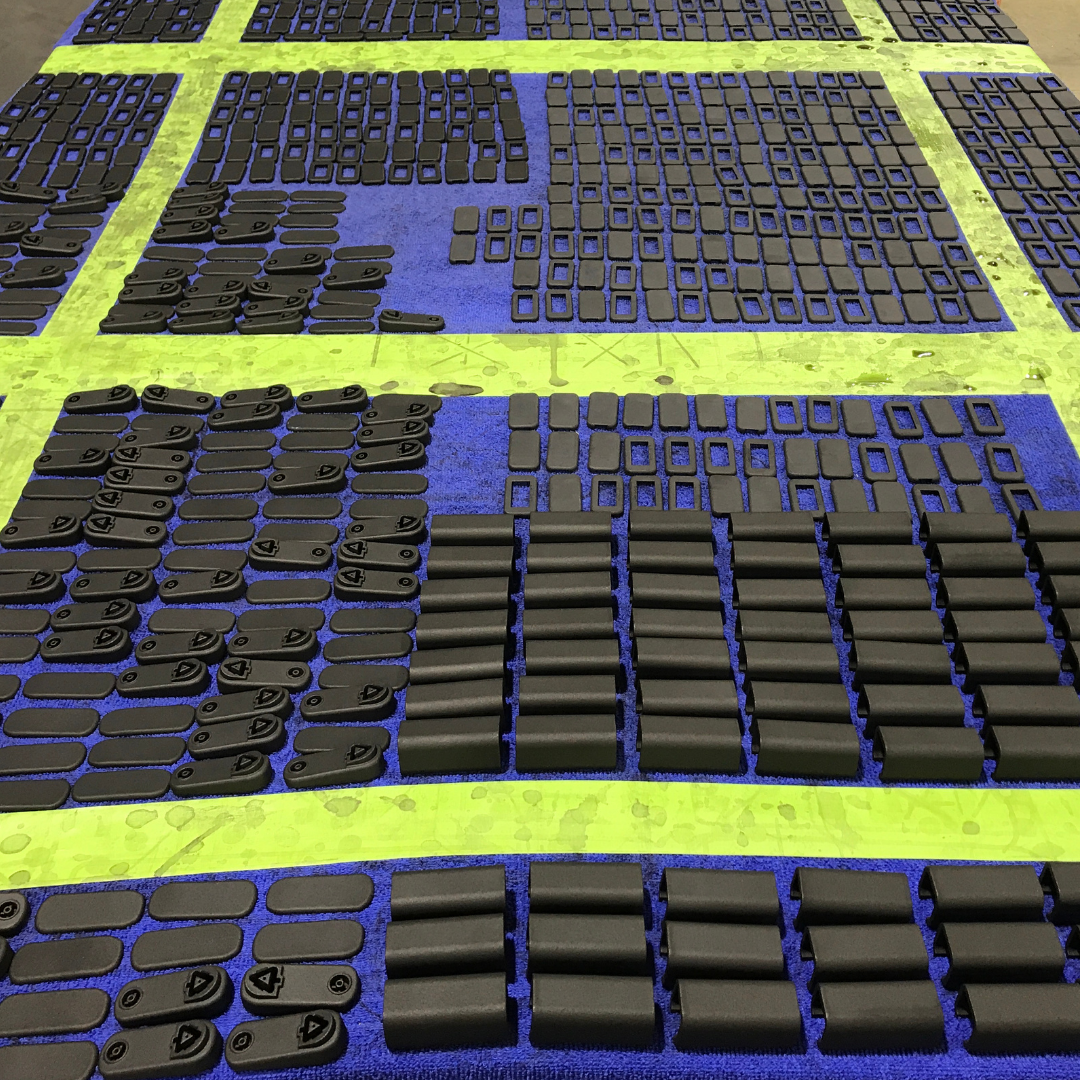

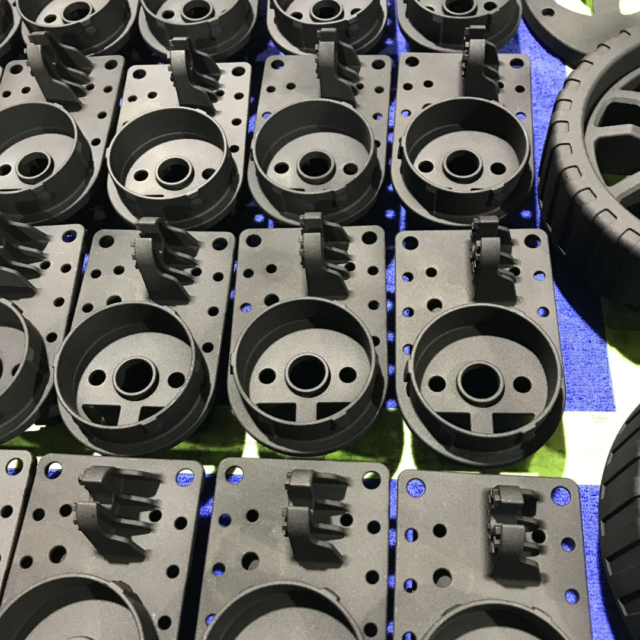

Aerosport Additive Short Run Production Parts

Aerosport Additive provides short-run production of products or parts of products for a wide range of customers. By completing small runs for a customer, Aerosport delivers benefits such as:

- Reduction of part product development times

- Elimination of waiting for weeks on tooling

- Production of short runs of parts before more standard production runs parts are available.

- Reduction of the number of parts and number of components to assemble

- Provision of a backup of parts during shortages

- Faster design iteration

For short-run production parts, Aerosport utilizes HP MultiJet Printers, and ETEC XTreme 8k Top-Down DLP Technology. Our equipment provides customers with functional parts with fine detail and great accuracy. This production style is considerably faster than the other additive manufacturing options or traditional manufacturing methods, such as injection molding.

HP MultiJet

HP MultiJet Technology gives Aerosport the capability to produce highest-quality prototypes as well as provide high-volume production manufacturing with several styles of finishing. The ability to rapidly produce parts in a production nylon material is game changing. In addition, there is now a variety of materials are available for use with these HP machines:

Click here learn more about our HP Equipment

ETEC Xtreme 8k Top-Down DLP Systems

Several Durachain materials will be exclusively available on the ETEC Xtreme 8k. Aerosport has purchased several ETEC Xtreme 8k printers and servers the avaiation, automation, medical, electronic, and military industries, among others. Click HERE to view a video of how Aerosport leverages this technology!

Click to learn more about ETEC Technology

AMT PostPro

Post-processing is an essential part of additive manufacturing. Typically, the pieces are smooth by hand. Still, this method tends to be slow, makes it challenging to produce consistent parts, and increases the piece’s overall cost. Therefore, Aerosport has invested in AMT’s fully automated post-processing solution. The equipment is designed specifically for the additive manufacturing industry and short production runs, transforming 3D-printed parts into production-ready parts consistently and quickly.