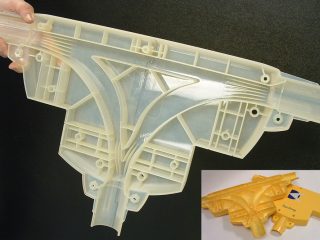

The SLA ® process uses a UV laser to photo-cure a variety of epoxy-based resins to “grow” 3D objects layer-by-layer from 3D electronic data (STL files). Because it is an additive process highly complex geometries can be built with assistance from support structures that are easily removed without adverse effect. The key advantage of SLA ® is its ability to rapidly produce highly detailed models with exceptional aesthetic qualities.

Key Benefits

• Fine detail and smooth surface finishing

• Accuracy within thousandths of an inch

• Variety of resins ranging in rigidity, detail, color, clarity, temperature tolerance

• Capable of light-duty functional and short-run low-temp tooling

• Can be painted and finished for presentation, demonstration, and photo reproduction

• Delivery of most parts usually in just a few working days

Key Uses

• Form, fit & function testing

• Quick concept and presentation models

• Master Part for RTV tooling and urethane part production

• Short run part prototypes

SLA MACHINES

Aerosport operates three SLA machines to provide the most flexibility to meet your schedule and part geometries.

SLA RSPro 600

Specifications

Smallest feature size: 0.010

Minimum layer thickness: 0.004

Accuracy: +/- .005

Platform size: 23.6 x 23.6 x 20

SLA 3500

Specifications

Smallest feature size: 0.012

Minimum layer thickness: 0.004

Accuracy: +/- .005

Platform size: 13.9×13.9×15

SLA Viper (2 machines)

Specifications

Smallest feature size: .0035”

Minimum layer thickness: .0025”

Accuracy: +/-.002”

Platform size: 10x10x10

Material Types

Aerosport offers six distinct resins for SLA builds. These resins cover the majority of characteristics necessary to achieve the look and feel you need.

Somos 9120 (PDF)

Our flexible resin option. 9120 is used to simulate flexible plastics like polypropylene and is slightly amber in color. (Runs in 3500 machine only)

Somos 10122 (PDF)

This WaterClear Ultra material is an optically clear resin with ABS-like properties and good temperature resistance. It produces colorless, functional, accurate parts that simulate an acrylic appearance.

Somos 11122 (PDF)

Our rigid material option. 11122 is excellent for clear part applications, and is water resistant. Similar to ABS plastics and can be finished to a water clear transparency. (Runs in 3500 and Viper machines)

EvoLVe (PDF)

This durable resin produces accurate, high-detailed parts and has been designed for easy finishing. It has a look and feel similar to finished traditional thermoplastics making parts from this material perfect for functional testing applications.

Finish Levels

Level 1 : Strip N’ Ship.

Parts are removed from the machine, supports taken off, cleaned, and then shipped.

Level 2 : Design Review and Evaluation Level.

Only major build layers sanded smooth (appearance side only) and a light bead blasting applied for uniform surface appearance.

Level 3 : Ready for paint.

All build layers sanded smooth with a fine grit (appearance side only) and primed.

Level 4 : Trade show/Appearance model quality.

All build layers sanded smooth with a fine grit (appearance side only unless specified). Parts are painted and textured.

Level 5 : Ultra Clear.

Clear parts are buffed and polished.