Aerosport’s DLP Tough Rubber Technology

Aerosport has purchased a VistionTech 8k 3D printer along with multiple vats of Adaptive3D’s flagship elastomer products Elastic ToughRubber™ 90 and Elastic ToughRubber 70.

“We have spent several years validating the market for 3d printed elastomeric parts utilizing other platforms,” said Aerosport CEO Geoff Combs. “But the top-down DLP printing platform combined with the superior performance of Adpative3D’s photoelastomer products generates a higher ROI to my business while delivering better quality parts to my customers. This is validated by over three months of backlog production capacity already booked for this program.”

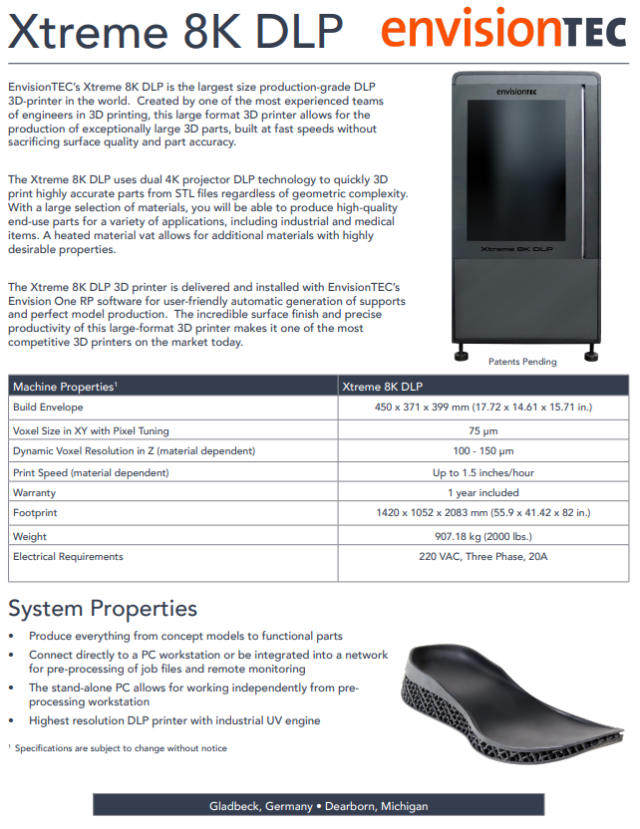

Xtreme 8K DLP

EnvisionTEC’s Xtreme 8K DLP is the largest size production-grade DLP 3D-printer in the world. Created by one of the most experienced teams of engineers in 3D printing, this large format 3D printer allows for the production of exceptionally large 3D parts, built at fast speeds without sacrificing surface quality and part accuracy.

Adaptive3D Materials

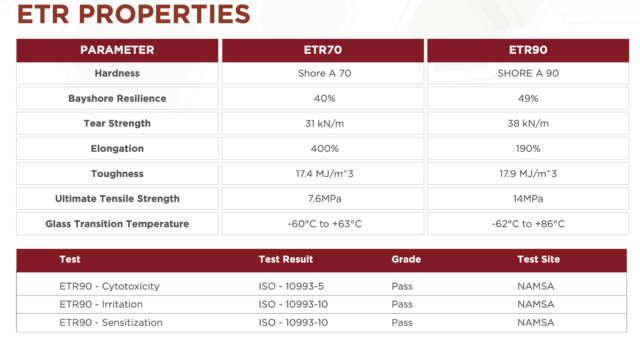

Elastic ToughRubber™ 90 and Elastic ToughRubber 70 Properties

Adaptive3D Materials Key Features & Benefits

Adaptive3D Materials Key Features & Benefits

– Flexibility and simplicity in design

– Modulus and performance comparable to foamed TPU

– Stable performance in all weather

– Durable and long lasting for end use

Applications & Use Cases

– Industrial Applications

– Foam-like lattice structuring

– Medical

– Automotive

– Consumer

– Orthotics

Download the Elastic ToughRubber™ 90 and Elastic ToughRubber 70 Brochure

Download the Elastic ToughRubber™ 90 Property Data Sheet

Download the Elastic ToughRubber™70 Properties Data Sheet

SOFT TOUGHRUBBER™

Designed for functional prototypes of audio ear buds, wearable electronics, and anatomical medical models, Soft ToughRubber™ (STR) delivers silicone feel and mechanical properties with the resolution and surface finish that DLP® printing provides.

Download The Soft ToughRubber Brochure

Download the Soft ToughRubber Properties Data Sheet