What is Fused Deposition Modeling?

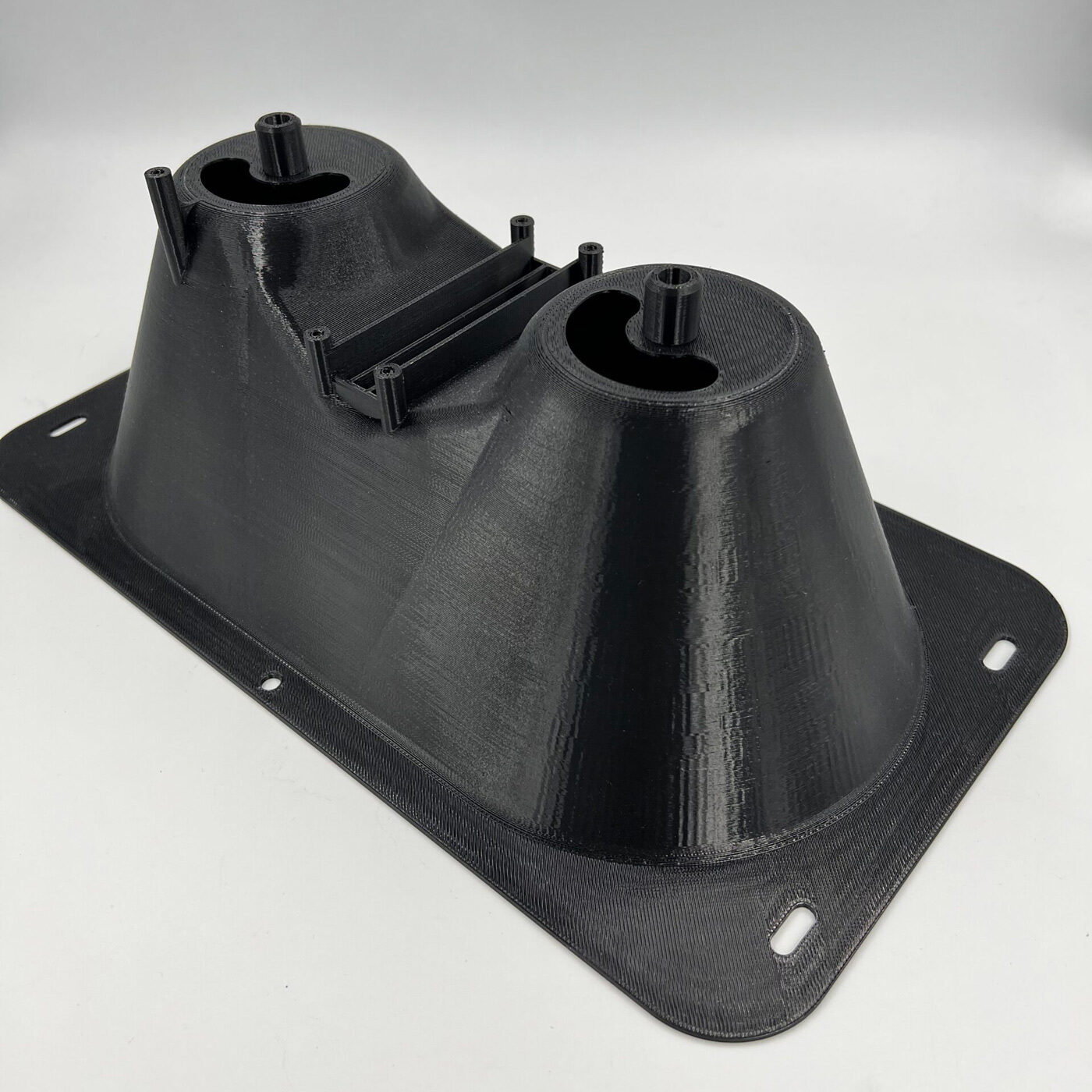

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is an additive manufacturing process that transforms digital designs into physical objects layer by layer. The process begins with a 3D digital model, which is sliced into cross-sectional layers. A thermoplastic filament, typically made of materials like ABS, PC, or Ultem, is then heated until it reaches a molten state. The FDM 3D printer deposits the melted filament layer by layer onto a build platform, solidifying each layer as it cools. The sequential layering and solidification create a three-dimensional object with the desired shape and structure. FDM is widely used for rapid prototyping, custom manufacturing, and producing functional parts across various industries due to its cost-effectiveness and versatility.

Key benefits and uses

Key benefits

- Swift iteration and testing, accelerating product development cycles

- Reduced production expenses due to affordable materials and straightforward processes

- Supports a wide range of thermoplastic materials, including ABS, PLA, PETG, and more allowing users to choose materials with specific properties like strength, flexibility, or heat resistance

Key uses

- Rapid design and prototyping due to rapid turnaround times

- Perfect for applications requiring lightweight, chemically-resistant materials

- A variety of finishing options offer versatility for automotive parts, aerospace components, sporting equipment, and even tool components

FDM production machine details

Aerosport Additive utilizes Stratasys® Fortus industrial FDM printers, with spacious build decks capable of accommodating parts measuring up to 14” x 14” x 16”.

Materials

| Material | Description | Information |

|---|---|---|

| PC | Polycarbonate FDM filament offers exceptional strength, heat resistance, and high impact durability, ensuring printed parts maintain shape and precision. With options for black, red, or standard white colors, it's ideal for durable applications like functional prototyping and manufacturing tooling, providing a cost-effective solution without compromising quality. | Download data sheet |

| PC-ABS | PC-ABS plastic combines polycarbonate's heat resistance with ABS's flexural strength, yielding one of the highest impact strengths among FDM thermoplastics. Ideal for functional prototyping, rugged tooling, and production parts, it offers a balance of durability and versatility for demanding applications. | Download data sheet |

| ABS | ABS-M30™ filament merges FDM® design flexibility with ABS’s strength and resilience. Lightweight yet robust, it suits various 3D printing needs. | Download data sheet |

| ASA | ASA filament, an all-purpose 3D printing thermoplastic, boasts superior mechanical properties, aesthetics, and UV resistance compared to ABS. With a diverse palette of 10 vibrant colors, it's perfect for various applications, offering durability and visual appeal unparalleled in FDM materials. | Download data sheet |

| Ultem 9085 | Ultem 9085 is a high-performance thermoplastic material known for its exceptional strength, stiffness, and resistance to heat, chemicals, and flame. Widely used in aerospace, automotive, and medical industries, it offers excellent dimensional stability and is ideal for advanced manufacturing processes. | Download data sheet |

| Ultem 1010 | ULTEM™ 1010 resin, a top-tier FDM® PEI thermoplastic, boasts high tensile strength, extensive chemical resistance, and remarkable thermal stability. Its autoclave compatibility suits sterilization needs, while its certified grade ensures adherence to medical and food safety standards. Available in natural color with breakaway support material. | Download data sheet |

| Nylon PA12 | FDM® Nylon 12 filament mirrors industrial PA12, offering robustness and high impact strength without brittleness. Ideal for snap-fit components and press-fit inserts due to its superior fatigue properties. Also suitable for jigs, fixtures, low-volume production, and accurate prototyping of injection molded parts. Available in black. | Download data sheet |

| Nylon-CF PA12 | Nylon-CF PA12 blends the durability and versatility of nylon with the strength and stiffness of carbon fiber. This composite material is ideal for producing lightweight yet robust parts, offering high chemical resistance and thermal stability, making it suitable for demanding industrial applications. | Download data sheet |

How can we help you manufacture with FDM?

The Aerosport Additive team provides guidance in the fused deposition modeling process. With top-notch 3D printers, we create parts with large build envelopes, programmable for simultaneous production, ensuring efficient prototyping and large-scale manufacturing with dependable material properties.