Aerosport Completes One-of-a-Kind Automotive Model Using Only 3D Printing!

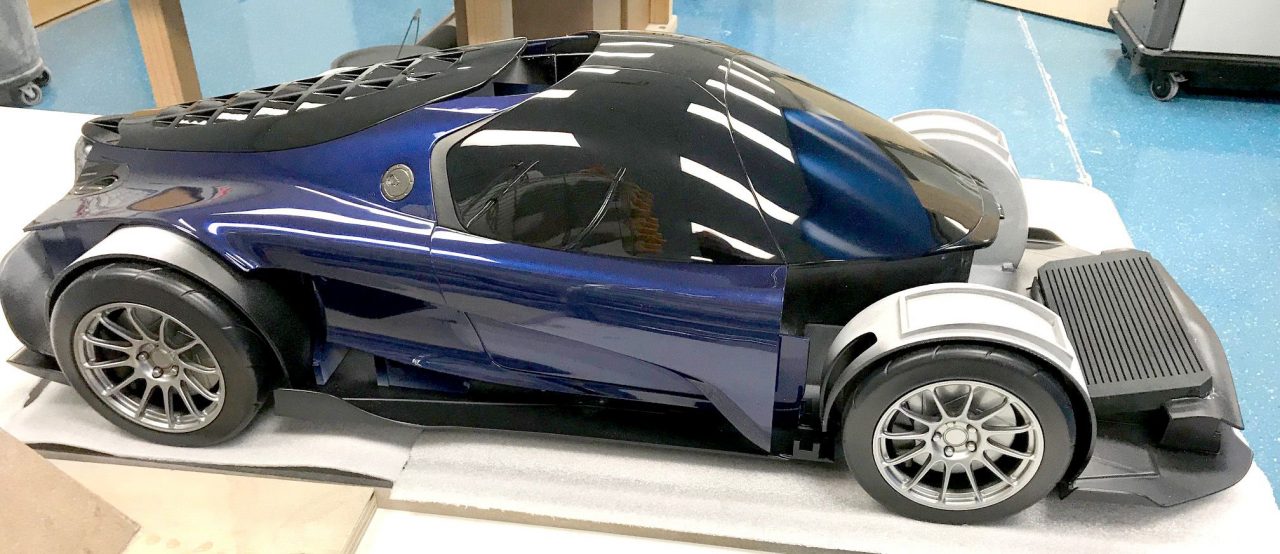

Scuderia Cameron Glickenhaus brought Aerosport Modeling and Design the unique project of building the one-off sales display model for their new 2019 SCG 004S super car.

~Click here for photo gallery~

Tuesday, January 23rd 2018: When Scuderia Cameron Glickenhaus first broke into the world of super car racing, it took that world by storm. Racing out to record times at many well-known racetracks around the world. SCG decided after a few years of racing that they would venture into the street legal production of a new automobile. That’s when in the fall of 2017 SCG contracted Aerosport Modeling & Design to produce a 1/5th scale replica model of their new street legal super car, the 2019 SCG 004s. This was a dream project for the model making crew at Aerosport, a prototype and 3D printing service bureau located in Columbus, OH. The team at Aerosport quickly formed their plan of action for the project around every part being created by in-house 3D printing capabilities.

Using the HP Jet Fusion 3D 4200 printer and several SL machines, Aerosport Modeling & Design was able to create the highest-quality printed parts for the model build. Most of the body panels, the chassis and the tires were printed out of HP PA12 nylon. The window sections, wheels and headlights were printed on a Uniontech RSPro 600 SL machine with Somos EvoLVe 128 resin. All of the clear lenses for the headlights and taillights were printed in Somos’ Water Clear 10122 resin in a Viper Si2. The full model was over 36 inches long and many of the builds took a considerable amount of time. Thanks to the high quality of the prints, the finishing time was greatly reduced over using prints from lower resolution machines.

“Aerosport got it’s start by making stunning, high-end models and has since provided customers across all industries the compelling and affordable prototyping services for more than 20 years,” said Geoff Combs, owner, Aerosport Modeling & Design. “We got the call on this project and I thought about how cool it would be to produce the entire model with our in-house 3D printing capabilities. We got the team together and started looking at all of the files that we had to work with and we came up with a list of which parts would be done in SLA material and which parts would work out best on our new HP Multi-Jet Fusion machine. After that meeting, we were off and printing parts for about a week, with many parts being split up to fit on the machines due to the overall size of the model.”

For more information on how to bring the advantages of Aerosport Modeling and Design to your business, contact us today!

About Aerosport Modeling & Design

Aerosport Modeling & Design, Inc. was established in September 1996. Since the beginning, our goals have been to produce the highest quality prototypes, appearance models, working models and machined parts possible and to meet or exceed client expectations 100% of the time. As a partner in the process, we aim to serve as an extension of our client’s own design and development team. For more than 20 years, Aerosport has served thousands of satisfied clients from many disciplines including automotive, medical, electronic, military, aviation, toy, consumer and more.

Contact:

Zac Holcomb

Aerosport Modeling & Design

For over 25 years, Aerosport Additive has served 1000’s of satisfied clients from many disciplines, including automotive, medical, electronic, military, aviation, toy, consumer, and more. We research and invest in the latest technologies and operating processes each year to help our customers stay competitive in the marketplace.

For over 25 years, Aerosport Additive has served 1000’s of satisfied clients from many disciplines, including automotive, medical, electronic, military, aviation, toy, consumer, and more. We research and invest in the latest technologies and operating processes each year to help our customers stay competitive in the marketplace. Aerosport Additive has selected Miles Manufactured Products as its Manufacturer Representative firm. Macay Hunter from Miles will be Aerosport’s key sales representative. Macay will support to Aerosport’s customers with account management and program development responsibilities.

Aerosport Additive has selected Miles Manufactured Products as its Manufacturer Representative firm. Macay Hunter from Miles will be Aerosport’s key sales representative. Macay will support to Aerosport’s customers with account management and program development responsibilities.