Posts by Shawn Tucker

Aerosport Completes One-of-a-Kind Automotive Model Using Only 3D Printing!

Aerosport Completes One-of-a-Kind Automotive Model Using Only 3D Printing! Scuderia Cameron Glickenhaus brought Aerosport Modeling and Design the unique project of building the one-off sales display model for their new 2019 SCG 004S super car. ~Click here for photo gallery~ Tuesday, January 23rd 2018: When Scuderia Cameron Glickenhaus first broke into the world of super…

Read MoreGlickenhaus SCG 004S Model Photo Gallery

Aerosport Modeling Helping Small Business Lower the Cost of Entry for Custom Products with HP Multi Jet Fusion Technology

Aerosport Modeling Helping Small Business Lower the Cost of Entry for Custom Products with HP Multi Jet Fusion Technology Industry leading quality, speed and cost savings available to customers across automotive, medical, electronic, military, aviation, toy and consumer markets Monday, October 23, 2017: Aerosport Modeling & Design, a 3D printing service bureau based in Canal Winchester,…

Read MoreAerosport Offers Production Quality Parts with HP Multi Jet Fusion Technology

Aerosport Modeling & Design Offers Production Quality Parts with HP Multi Jet Fusion Technology Industry leading quality, speed and cost savings available to customers across automotive, medical, electronic, military, aviation, toy and consumer markets Thursday, October 5, 2017: Aerosport Modeling & Design, a 3D printing service bureau based in Canal Winchester, OH, has added services…

Read MoreNew HP 3D Printer is Up and Running!

Our New HP Multi-Jet Fusion 3D Printer is Up and Running! Aerosport Modeling & Design is proud to announce that our new HP Multi-Jet Fusion 3D Printer is installed and is already turning out lots of awesome parts! This new capability is allowing us to continue providing the highest-quality prototypes as well as now providing high-volume…

Read MoreMulti-Jet Fusion 3-D Printer

HP Multi-Jet Fusion 3D Printer Coming Soon! Aerosport Modeling & Design is proud to announce that their new HP Multi-Jet Fusion 3D Printer is coming soon! This new capability allows Aerosport to continue providing the highest-quality prototypes as well as now providing high-volume production manufacturing with several styles of finishing. HP’s groundbreaking Multi-Jet Fusion technology…

Read MoreOur Largest SLA Build To Date!

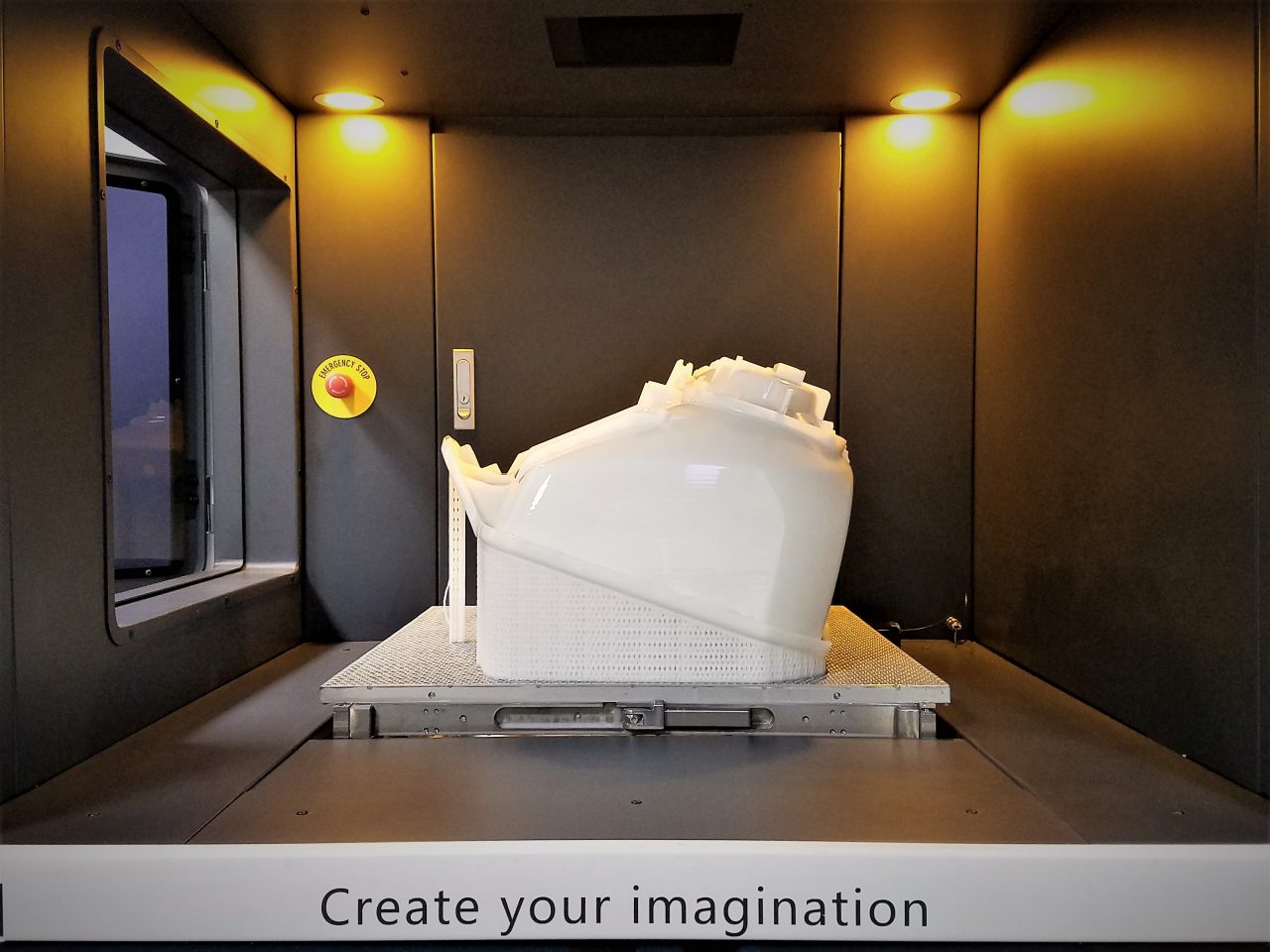

Our New SLA Machine Just Completed It’s Largest Build Yet. Our Union Tech RSPro 600 SLA machine at Aerosport Modeling just completed it’s largest build to date! We use DSM Somos EvolVe 128 resin in this large platform machine. With a build platform measuring 600x600x500mm (23.6×23.6×19.6″) we are able to build large items like this…

Read MoreAdditional SLA Capacity

Additional SLA Capacity Aerosport Modeling has just added additional capacity to our 3D printing department. We now have a new RSPro 600 SLA machine. We will be running Somos EvolVe in this Machine and it has a build size of 23.6” x23.6” x 20” or 600x600x500 mm. We now have 5 SLA machines and…

Read MoreHydrokinetic Power Generator Test in India

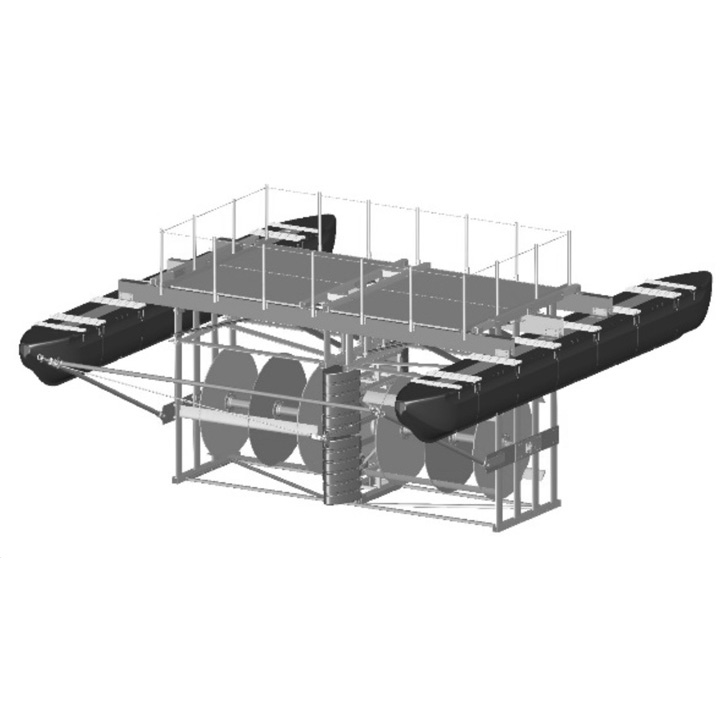

[bt_section][bt_row][bt_column width=”1/1″][bt_text] HYDROKINETIC Power Generator going for testing in India Aerosport has just Shipped the second Hydrokinetic Generator to India for testing in the Chilla Canal. Our client is excited about testing these 2 new units in the environment they were designed for. These units use the canal water flow to turn the generator. Aerosport…

Read MoreCheers to 20 Years

Cheers to 20 Years! In September 2016 Aerosport Modeling & Design, Inc. celebrated its’ 20th anniversary with a pig roast for over 125 clients, vendors, family & friends. Music was provided by the local group Bird Shack featuring guitarist Jeff Ciampa. The event was held at the company headquarters in Canal Winchester on a very…

Read More