HP Multi-Jet Fusion 3D Printer

Aerosport Additive has several HP Multi-Jet Fusion 3D Printer installed and producing production parts! This capability is allows us to continue providing the highest-quality prototypes as well as now providing high-volume production manufacturing with several styles of finishing. The ability to rapidly produce parts in a production nylon material changes the game for our customers. Give us a call or send us your file and let us show you what we can do for you. — From the prototype to the finished product with Aerosport Additive.

This new Multi-Jet Fusion technology allows faster prototyping and short-run production with end-use part material reliability. This production style is considerably faster than the other additive manufacturing options or traditional manufacturing methods, such as injection molding. We will be able to offer clients a much more cost-efficient path to final production parts while receiving prototype parts in the end-use material from the beginning of the design process.

Better Quality, Speed, Cost and Control

Leveraging decades of research and expertise in precision mechanics, microfluidics and materials sciences, HP has developed a system that can control part properties voxel by voxel (a voxel is the 3D printing equivalent of a pixel). This level of control means extreme precision and optimal mechanical properties in producing fully functional prototypes and final parts, and will reinvent manufacturing in the future.

HP High-Reusability PA12 Nylon

The resulting parts are extremely strong, highly accurate and have a surface finish that makes them ideal for mechanical testing and production manufacturing. All this at speeds up to 10x faster than legacy technologies.

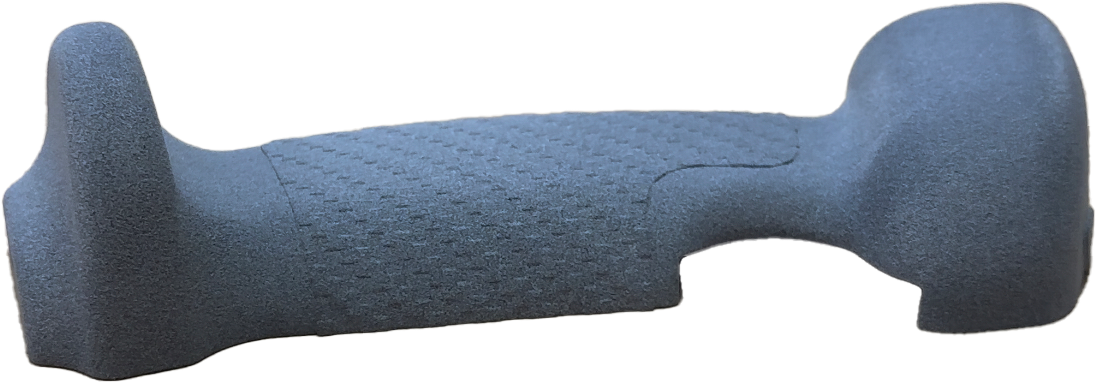

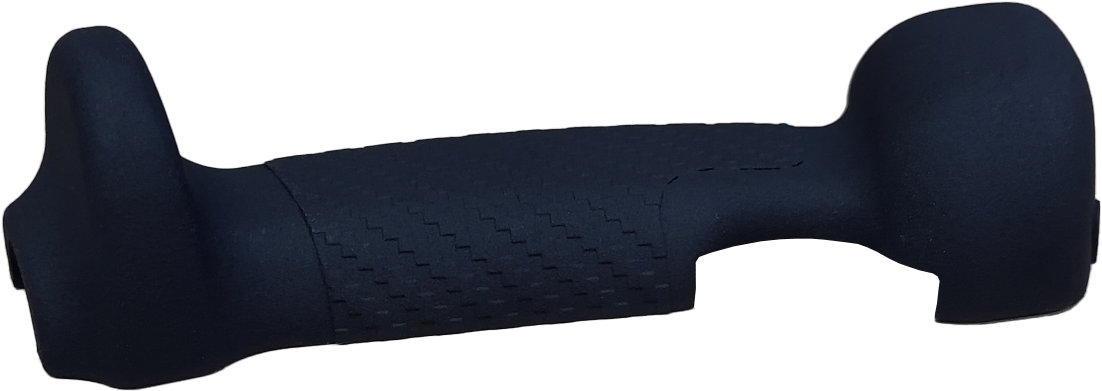

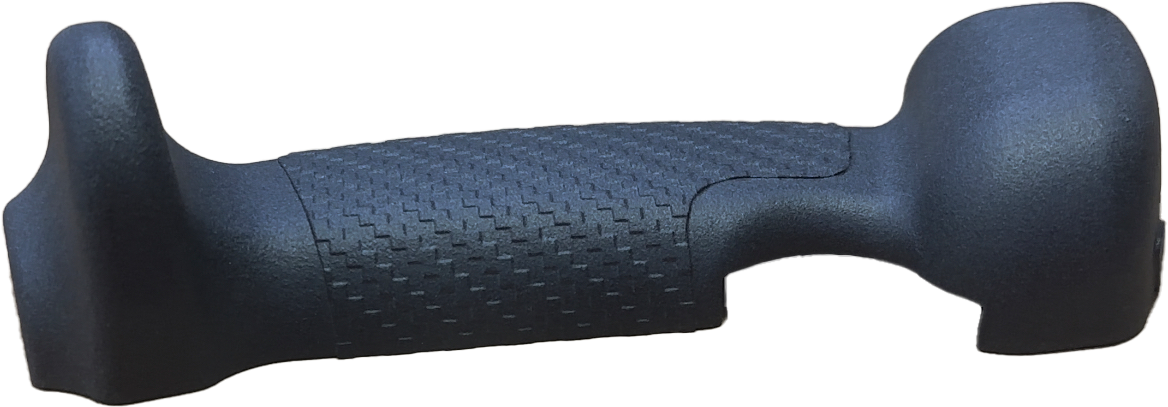

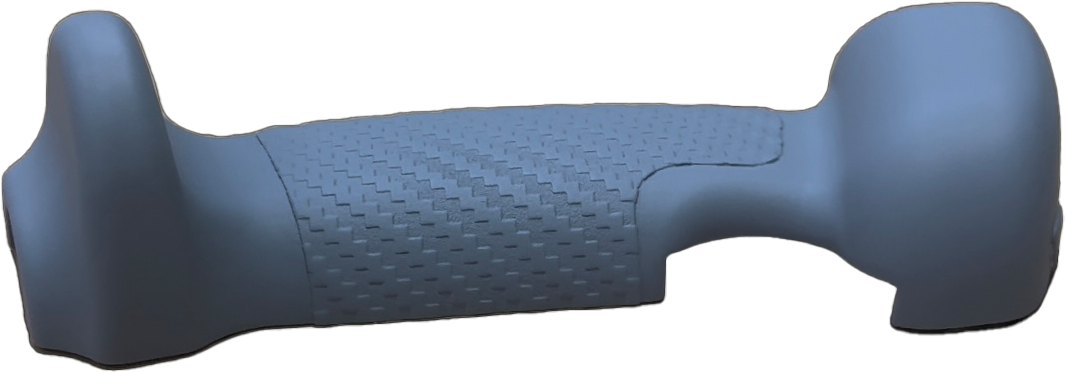

Finishing Options

AeroSport Additive offers a wide variety of different finishes, including vapor polishing, vapor smooth, and Cerakote.

Sample Swatch Key

- Bead Blasted (Default Finish)

- Bead Blasted, Dyed Black

- Shot Peened

- Shot Peened, Dyed

- Vapor Polished

- Vapor Polished, Dyed

VIEW OUR VAPOR POLISHING PROCESSES HERE

| Mechanical Properties | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Property Description | Test Standard | Metric | English | ||||||||

| Tensile Modulus | ASTM D638 | ||||||||||

| X Direction | 1,700 MPa | 245,000 psi | |||||||||

| Y Direction | 1,700 MPa | 245,000 psi | |||||||||

| Z Direction | 1,800 MPa | 260,000 psi | |||||||||

| Tensile Strength | ASTM D638 | ||||||||||

| X Direction | 48 MPa | 6,960 psi | |||||||||

| Y Direction | 48 MPa | 6,960 psi | |||||||||

| Z Direction | 48 MPa | 6,090 psi | |||||||||

| Elongation at Break | ASTM D638 | ||||||||||

| X Direction | 20% | ||||||||||

| Y Direction | 20% | ||||||||||

| Z Direction | 15% | ||||||||||

| Thermal Properties | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Property Description | Test Standard | Metric | English | ||||||||

| Heat Deflection Temp (@ 0.45 MPa) | ASTM D648 | 175 °C | 375 °F | ||||||||

| Heat Deflection Temp (@ 1.82 MPa) | ASTM D648 | 95 °C | 203 °F | ||||||||

| Density | ASTM D792 | 1.01 g/cm3 | 0.036 lb/in3 | ||||||||

Prototyping Benefits

- Excellent detail and surface quality

- Accuracy within thousandths of an inch

- Can be finished and painted for show-quality appearance while maintaining production functionality of many features, including snap- and clip-features

- Delivery of most parts with in a few working days

- Ability to prototype in an end-use, production PA12 nylon material

Production Benefits

- No traditional manufacturing constraints

- Durable PA12 Nylon material

- Cost-efficiency

- No mold costs

- Ability to modify the design as you go

- Time to market is greatly reduced – getting your product out there before your competition

Related certificates and documents