Stereolithography (SLA) 3D Printing Guide for Product Developers

Stereolithography 3D printing (SLA) is revolutionizing the way industries create highly detailed and accurate prototypes, functional parts, and more. Using resin and ultraviolet light to cure photosensitive polymers, SLA offers precision that is unmatched by many other 3D printing technologies.

In this article, we’ll explore the inner workings of stereolithography 3D printing, its advantages and disadvantages, and how to choose the best SLA 3D printer for your needs. If you’re interested in understanding why SLA technology is a game-changer, keep reading.

Outline

- Introduction to SLA: What is Stereolithography 3D Printing?

- How Does SLA Technology Work?

- What Materials Are Used for SLA Printing?

- Advantages and Disadvantages of SLA Technology

- How Accurate is SLA Printing?

- What Industries Benefit from SLA 3D Printing?

- Comparing SLA to Other 3D Printing Technologies: FDM, SLS, and More

- The Benefits of Using SLA 3D Printing for Creating Prototypes

1. Introduction to SLA – What is Stereolithography 3D Printing?

Stereolithography (SLA) is one of the first 3D printing technologies ever developed, and it remains one of the most popular today due to its high precision and versatility. SLA machines create 3D objects by selectively curing layers of liquid resin using ultraviolet light. The process enables engineers and designers to produce parts with intricate details, smooth surfaces, and tight tolerances.

This additive manufacturing process was first commercialized in the 1980s and has since been widely used for rapid prototyping, medical devices, and even end-use parts. With advancements in SLA systems, stereolithography continues to play a pivotal role in industrial and consumer applications.

2. How Does SLA Technology Work?

SLA technology involves the use of liquid resin contained in a vat. A UV light source or ultraviolet laser traces the design of each layer, curing the resin to form solid parts. The build platform gradually lowers into the resin tank, allowing a new layer of resin to be cured on top of the previous one. This layer-by-layer process repeats until the entire 3D model is complete.

One of the most innovative aspects of SLA printing is its ability to create 3D printed parts with complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods. The resin 3D printing process is highly accurate and offers smooth surface finishes, making it ideal for industries that demand precision.

3. What Materials Are Used for SLA Printing?

SLA printing uses a variety of resin materials depending on the application. Common SLA materials include:

- Standard Resins – Used for creating prototypes with smooth finishes.

- Tough Resins – Designed for durable, functional prototypes that require impact resistance.

- Flexible Resins – Used in applications that need parts with flexibility.

- Medical Resins – Biocompatible resins used in medical devices and dental models.

These resins are curable by ultraviolet light and offer a wider range of applications compared to other 3D printing technologies.

4. Advantages and Disadvantages of SLA Technology

Like any manufacturing technology, there are pros and cons associated with a process that may affect suitability for specific projects. Some advantages and disadvantages of SLA 3D printing are:

| Advantages | Disadvantages |

|---|---|

| High Precision SLA technology can achieve incredibly fine details and smooth surfaces, making it ideal for prototypes and 3D printed parts that require tight tolerances. Smooth Surface Finish Unlike FDM or SLS printing, SLA parts come out with a smooth finish. Material Variety SLA 3D printing supports a broad range of resins that can be tailored for different mechanical and thermal properties. | Post-Processing Required Parts must be cleaned and often cured further under ultraviolet light after printing to reach their full mechanical properties. Material Waste Unused liquid resin cannot always be reused, which can lead to waste. Fragility Some SLA printed parts are more brittle than those produced by other 3D printing methods, depending on the type of resin used. |

5. How Accurate is SLA Printing?

The accuracy of SLA is one of its most significant advantages. With layer thicknesses as fine as 25 microns, SLA printers can produce 3D objects with extremely fine details, which is why they are commonly used in industries like dental, aerospace, and engineering. The quality of SLA is unmatched in terms of surface finish, making it perfect for prototypes that need to mimic the final product.

Additionally, inverted stereolithography and top-down SLA methods offer different approaches for increasing accuracy and reducing material waste, ensuring that SLA 3D printers are versatile enough for a variety of applications.

6. What Industries Benefit from SLA 3D Printing?

Although applicable to any industry, certain industries benefit from the precision and material flexibility of SLA technology, including:

- Medical Devices – Used for creating accurate medical models and surgical guides with biocompatible resins.

- Aerospace – Engineers can utilize the SLA 3D printing process to create functional prototypes and 3D printed parts that require high precision.

- Jewelry – Modern craftsmanship! SLA printers can be used to produce intricate jewelry designs with detailed patterns and smooth finishes.

Thanks to its accuracy and material versatility, SLA continues to be a favorite among industries that need high-performance prototypes and 3D printed parts.

7. Comparing SLA to Other 3D Printing Technologies: FDM and SLS

While SLA excels in detail and surface finish, other 3D printing technologies such as FDM and SLS offer different benefits:

- FDM (Fused Deposition Modeling) – FDM is often more cost-effective and better for rapid, lower-resolution parts but lacks the fine detail of SLA.

- SLS (Selective Laser Sintering) – The SLS process uses powder materials to create parts, making it ideal for strong, functional components, but it lacks the smooth finishes offered by SLA printing.

Each 3D printing technology has its strengths, but SLA tends to stand out for applications where precision and surface quality are critical.

8. The Benefits of Using SLA 3D Printing for Creating Prototypes

Product engineers can use the SLA 3D printing method for rapid prototyping, allowing them to create functional prototypes with high precision. The ability to quickly iterate and test designs is crucial for industries like automotive and consumer electronics, where time-to-market is essential.

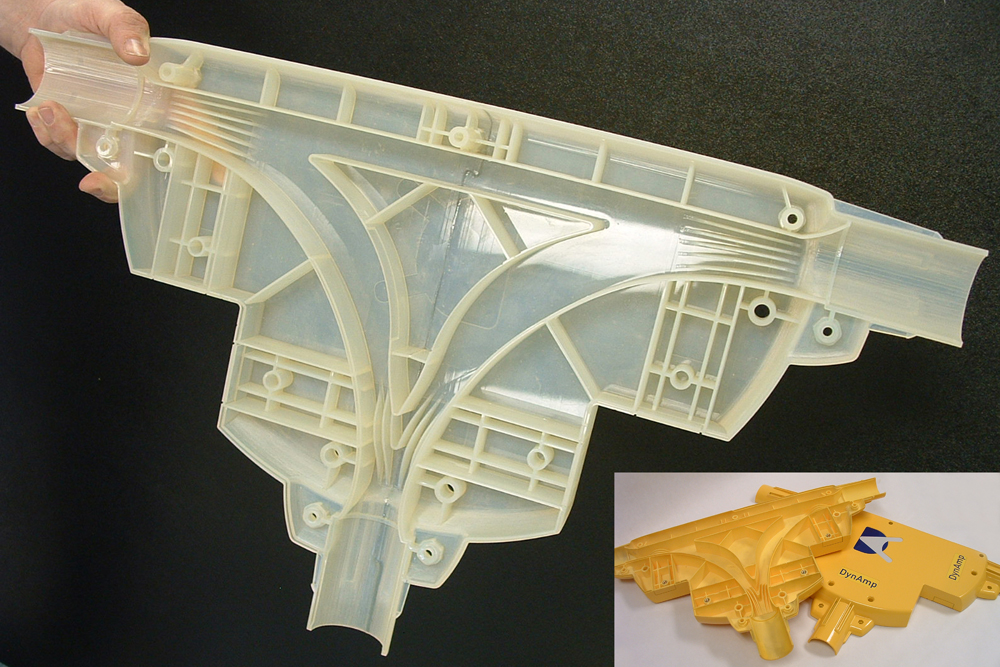

Another advantage of SLA 3D printing is its capability to produce complex designs and shapes that would be difficult or impossible to achieve with traditional manufacturing methods. This flexibility allows engineers to push design boundaries and explore more innovative solutions without being restricted by tooling limitations.

For instance, in medical device development, SLA can create intricate components like vascular models or implant prototypes with fine details that help surgeons and researchers evaluate their performance in real-life applications.

SLA technology also enables the creation of prototypes with properties that mimic final production parts, making it easier to test form, fit, and function before committing to mass production.

For example – a company developing a new car dashboard can use SLA printing to produce a detailed, functional prototype that simulates the final material properties. Engineers can then test the ergonomics, fit of components like switches and displays, and even simulate real-world environmental factors (through processes like wind tunnel testing) on the prototype, all before investing in expensive molds for mass production.

Key Takeaways

- SLA is one of the first and most precise 3D printing technologies.

- It uses UV light to cure liquid resin layer by layer, creating smooth and detailed prototypes.

- SLA 3D printing offers superior precision, smooth surface finishes, and material versatility, making it ideal for industries that require high-performance prototypes.

- Resin materials used in SLA systems provide options for various applications, from general-purpose prototyping to specialized medical or engineering parts.

- While SLA excels in detail, it typically requires some post-processing and careful material handling to ensure optimal results.

- SLA remains one of the most effective 3D printing technologies for industries demanding high accuracy and intricate designs.

- SLA enables rapid prototyping with high accuracy, allowing quick design iterations, complex geometries, and prototypes that mimic final production properties for real-world testing, such as car dashboards or medical components.

By understanding how stereolithography 3D printing works and its advantages, engineers, designers, and manufacturers can leverage this technology to accelerate innovation and improve product development.

Frequently Asked Questions (FAQs)

- What is the difference between SLA and other 3D printing technologies like FDM and SLS?

SLA (Stereolithography) uses a UV laser to cure liquid resin into solid layers, providing high accuracy and smooth surface finishes. FDM (Fused Deposition Modeling) uses heated plastic filaments, which are extruded layer by layer, resulting in rougher finishes but lower material costs. SLS (Selective Laser Sintering) uses a laser to fuse powdered materials, typically thermoplastics, into solid parts and is ideal for durable, functional parts but lacks the surface smoothness of SLA. - What kind of materials can I use with an SLA 3D printer?

SLA printers use photopolymer resins, which are available in different types, such as standard, tough, flexible, heat-resistant, and biocompatible resins. Each material offers unique properties, allowing you to choose based on the application, whether it’s rapid prototyping, medical devices, or engineering parts. Aerosport Additive have a variety of these materials available for SLA applications. - How does post-processing work in SLA 3D printing?

After the SLA print process is complete, the printed parts must undergo post-processing steps to remove excess resin, and additional UV curing to harden the object fully. Depending on the part’s use, sanding or polishing may be needed to achieve a smooth final finish. - What are the main advantages of using SLA for prototyping?

SLA 3D printing offers high precision, fine details, and quick turnaround times which makes it ideal for creating accurate prototypes. The smooth surface finish reduces the need for post-processing, and the ability to use specialized resins allows for functional prototypes that can withstand mechanical testing. - What industries benefit the most from SLA 3D printing?

SLA printing is great for making custom parts for any industry, really. But industries requiring high precision and intricate designs, such as healthcare, aerospace, automotive, and consumer electronics, benefit the most from SLA technology. It’s commonly used for applications such as medical device prototypes, dental models, and custom jewelry. - Can SLA 3D printing be used for end-use parts or just prototyping?

Yes, SLA 3D printing is not limited to prototyping. With the right resins, SLA can produce end-use parts, especially in industries like dental, where precision and smooth surface finishes are crucial. Some specialized SLA resins are designed for high-strength or biocompatible applications, making SLA viable for low-volume production runs. - Can SLA 3D printing be used for large-scale projects?

While SLA 3D printing excels in precision, it is typically used for smaller or medium-sized parts due to the limited build volume of most desktop SLA printers. However, some product designs can be produced in sections (which can even help with transportability), allowing the SLA process to handle bigger projects. - Is SLA 3D printing environmentally friendly?

SLA printing uses resin, which may generate waste during the printing process and require careful disposal. However, the process generally produces less waste compared to traditional subtractive manufacturing methods. Additionally, SLA’s ability to produce prototypes quickly can reduce the need for multiple iterations, conserving resources in the long run.