To get production quality urethane castings you need two things RTV silicone tooling, and vacuum casting machines. Vacuum casting gives you consistent void free urethane parts that can be molded in color and texture. From small intricate internal parts to large appliance housings Aerosport can use one of it’s two vacuum casting machines to make one part or 100. Aerosport Additive is your urethane expert.

In the RTV (Room Temperature Vulcanized) tooling process, liquid silicone rubber is poured around a master pattern. The resulting mold is pulled from the pattern and cured, then subsequently used to cast urethane parts. The key advantage of this process is being able to obtain higher quantities of prototypes at relatively low cost.

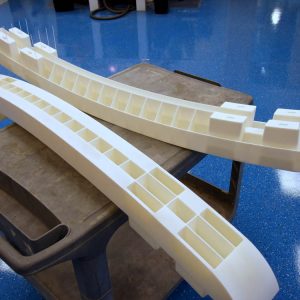

Aerosport starts by producing a master pattern exactly like the outside of the desired part. The part is then finished to the desired finish/texture.

Urethane castings:

• Provide precision and premium plastic prototypes.

• Are used to assist engineering design before hard tool.

• Offer low cost tooling, allowing easy modification.

• Reduce time to market.

• Are used to evaluate potential markets.

• Assist in UL approval and in-house testing.

• Offer aesthetic application where appearance is critical.

• Are used in sales presentation and marketing shows.

Delivery of part(s) usually in 1-2 weeks.

After the master is complete, a silicone mold is created. Once the mold is created, Aerosport fills the mold with the correct amount of material to achieve the desired wall thickness and the mold is rotated in two different axes for a desired amount of time.

There are a wide variety of materials available. Materials can simulate HDPE, ABS, Nylon, PC, Styrene and TPE Shore A materials. Hardness ranges from 20 Shore A to 90 Shore D materials.

Urethanes molded in Shore A Durometer and color Aerosport also offers Fire retardant prototypes cast in UL94V0 rated urethanes.

MCP Vacuum Casting

Worldwide, the most widely used process for replicated Rapid Prototyping Models.

German engineered the MCP vacuum casting system can run parts as large as 30x35x30 inches.

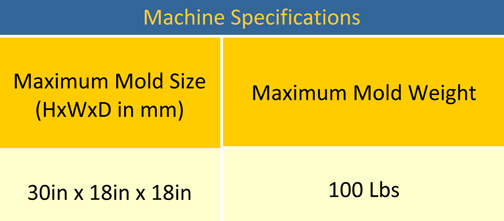

Max. Mold Size (HxWxD) in

14lbs. / 6.5 Kg

MK Technology Vacuum Casting

Also German engineered the MK can produce flawless urethane over molds in addition to flawless urethane parts. Utilizing vacuum and pressure, our Urethane Casting process produces parts in a variety of materials, colors and textures providing the look and feel of finished production. Aerosport’s techniques allow us to integrate multiple colors and textures into a single part. Master patterns can be made by rapid prototype process or machined and fabricated for highest precision. Aerosport’s Urethane Casting process is ideal when your program calls for a fast and cost effective low volume solution.

Roto Casting

Aerosport starts by producing a master pattern exactly like the outside of the desired part. The part is then finished to the desired finish/texture.

After the master is complete, a silicone mold is created. Once the mold is created, Aerosport fills the mold with the correct amount of material to achieve the desired wall thickness and the mold is rotated in two different axes for a desired amount of time.

Materials

Roto Casting can use many of the same materials as urethane cast parts. There are a wide variety of materials available. Materials can simulate HDPE, ABS, Nylon, PC, Styrene and TPE Shore A materials. Hardness ranges from 25 Shore A to 85 Shore D materials.

Possible uses

• Bottles of all types • Jars / Vases • Tanks (gas tanks, water reservoirs etc.) • Statues • Large Housing • Child’s Toy