Rapid Prototyping with Stereolithography (SLA)

Stereolithography (SLA), a revolutionary 3D printing technology developed nearly 40 years ago, is a cornerstone technology in additive manufacturing (AM) – a technology well-suited for rapid prototyping, offering unparalleled accuracy and detail.

How SLA Works

SLA utilizes ultraviolet (UV) lasers to cure thin layers of liquid resin into solid parts. The process begins with a UV laser drawing patterns onto the surface of a resin bath, turning the liquid into a solid layer.

Once a layer is cured, a fresh layer of uncured resin is applied, and the process repeats until the part is fully formed. After the build, post-processing occurs applying additional UV curing to solidify its surface and deliver a smooth finish.

SLA’s Precision and Capabilities

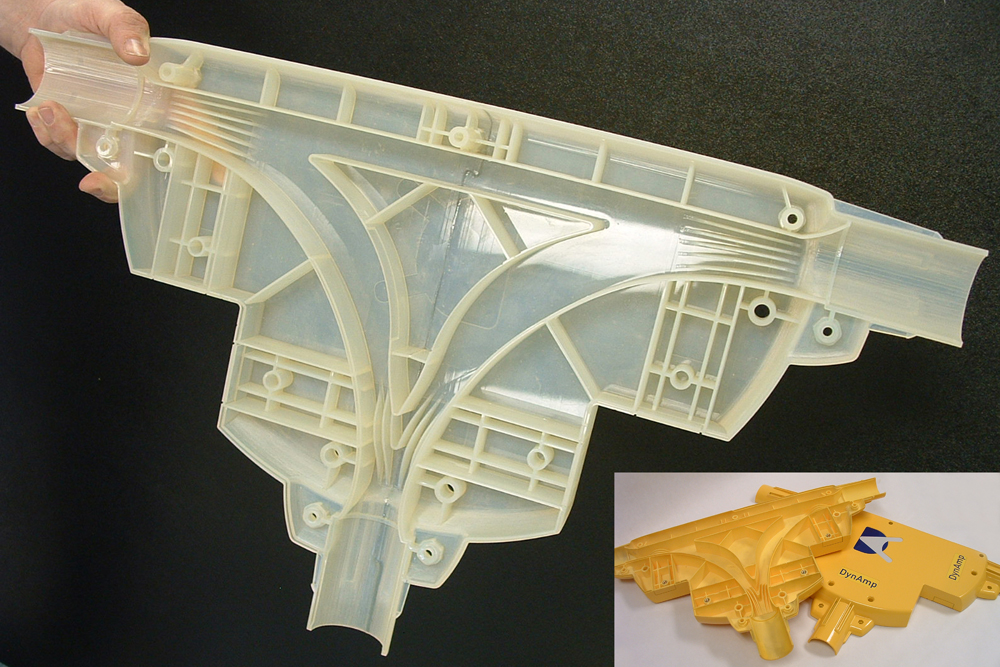

SLA excels in part accuracy and surface finish compared to other 3D printing technologies like selective laser sintering (SLS) and fused deposition modeling (FDM). It offers resolutions ranging from normal to high and micro, with layer thicknesses between 0.004 inches and 0.0025 inches. This high resolution enables the creation of parts with intricate details and minimal part lines.

Aerosport Additive’s SLA 3D printers accommodate large prototypes with a maximum build volume of 23.6 inches by 23.6 inches by 21 inches, making it suitable for prototyping larger products like yard equipment, agricultural machinery, or aircraft applications.

Modern SLA Resins and Materials

Current SLA machines offer a diverse range of resins that mimic various thermoplastics. Aerosport Additive offers the following materials for SLA production:

- Somos 9120 (PDF)

Our flexible resin option. 9120 is used to simulate flexible plastics like polypropylene and is slightly amber in color. (Runs in our SLA 3500 machine only) - Somos 10122 (PDF)

This WaterClear Ultra material is an optically clear resin with ABS-like properties and good temperature resistance. It produces colorless, functional, accurate parts that simulate an acrylic appearance. - Somos 11122 (PDF)

Our rigid material option. 11122 is excellent for clear part applications and is water resistant. Similar to ABS plastics and can be finished to a water clear transparency. (Runs in our 3500 and Viper machines) - EvoLVe (PDF)

This durable resin produces accurate, high-detailed parts and has been designed for easy finishing. It has a look and feel similar to finished traditional thermoplastics making parts from this material perfect for functional testing applications.

SLA is best suited for prototyping where form and fit are crucial and functional performance under extreme conditions is not a primary concern.

It’s important to note that while SLA resins mimic the properties of their thermoplastic counterparts, they often do not match the durability and strength of sintered, cast, machined, or molded parts. Other AM manufacturing processes such as HP MJF printing is often a better fit for these instances. However, for accuracy and precision in product design, SLA 3D printing can’t be beat!

Design Considerations for SLA Parts

When designing for SLA, certain considerations are crucial:

- Small holes – Extremely small holes, especially those smaller than 0.005 inches, may be problematic due to the resin’s high viscosity. Such features can be challenging during the post-build process.

- Mechanical joints – moving joints may not be as resilient as production materials

- Wall thickness – Thin walls, particularly those less than 0.025 inches to 0.040 inches thick, should be avoided to ensure structural integrity.

- Temporary Supports – During the build process, temporary structures may be used to support the part. These are typically removed before delivery, leaving minimal evidence of their presence. The orientation of the part can also affect the cosmetic appearance of some surfaces.

- Large parts – For parts larger than the build envelope of 23.6” x 23.6 x 21”, a design may need to be divided into multiple sections, then joined post-production.

As with any manufacturing process, there are design limitations to be aware of, and SLA printing is no different. Knowledge of these limitations beforehand ensure a more painless design/production process. Adding value to our process is our team’s high level of understanding these constraints. We work with you to help alleviate potential issues before encountering them after part production.

Finishing Options for SLA Parts

Aerosport Additive offers various finishing levels for SLA parts to enhance their appearance and functionality:

- Level 1 : Strip N’ Ship

Parts are removed from the machine, supports taken off, cleaned, and then shipped. - Level 2 : Design Review and Evaluation Level

Only major build layers sanded smooth (appearance side only) and a light bead blasting applied for uniform surface appearance. - Level 3 : Ready for paint

All build layers sanded smooth with a fine grit (appearance side only) and primed. - Level 4 : Trade show/Appearance model quality

All build layers sanded smooth with a fine grit (appearance side only unless specified). Parts are painted and textured. - Level 5 : Ultra Clear

Clear parts are buffed and polished.

The Role of SLA in the Design Process

Stereolithography plays a critical role between digital models and final manufactured parts.

SLA 3D printing allows designers to touch and test prototypes within days, helping to identify and correct costly mistakes early in the development process. Traditional manufacturing methods are much more time-consuming and resource intensive. SLA’s ability to speed up turnaround is essential in an iterative design process, where multiple versions of a product may need to be evaluated and refined.

In an industry where time is money, rapid iteration accelerates time to market, allowing companies to leverage manufacturing flexibility and boost profits by delivering products sooner. With SLA production enhancing the innovation cycle, designers can quickly and cost-effectively produce prototypes, maximizing their chances of achieving the ideal product.

An integrated approach to design, prototyping, and production offers significant advantages in product development by streamlining the entire process. First, by combining these stages, you ensure smooth transitions from design to final product, reducing time-to-market. This integration helps in spotting design flaws early and adjusting swiftly, which can prevent costly errors later.

Moreover, aligning these phases promotes cost efficiency. The collaborative nature of an integrated system means less back-and-forth between separate teams, which often leads to delays and miscommunications. This seamless communication can significantly cut down on overhead costs, allowing more resources to be allocated towards innovation.

An integrated approach enhances flexibility. It allows for rapid prototyping, enabling iterative testing and feedback incorporation. This is crucial in today’s fast-paced markets where consumer demands can shift quickly. By having the ability to adapt at every stage, companies can stay competitive and responsive.

This synergy accelerates development timeframes and reduces expenses, ensuring products that are not only high-quality but also meet market needs precisely when they arise.

What is the Typical Lead Time for SLA 3D Printed Parts?

When it comes to SLA 3D printing, the lead time can vary, but typically ranges between two to three days. This includes the entire process from initial order placement to when the parts are ready for shipment.

Several factors can influence this timeframe:

- Complexity of the Design: More intricate designs may require additional build and post-processing time.

- Order Volume: A larger number of parts can extend production time.

- Printer Availability: Busy production schedules can affect the timeline.

By planning ahead and discussing specific requirements with your provider, you can ensure that your project stays on track and meets your deadlines.

Questions About SLA 3D Printing for your Prototype?

SLA’s advanced capabilities and versatile material options make it a powerful tool for creating accurate and detailed prototypes. Whether for testing complex designs or producing large-scale models, SLA remains a key player in the evolution of additive manufacturing.

If you’re considering an additive manufacturing method for your product prototype, please contact us with any questions or concerns you may have – we’ve been working with (and perfecting) our SLA manufacturing processes since the mid-1990’s.

If you have drawings for your prototype, you can use our Request a Quote form to begin the process. For SLA submissions, we accept STL files – the native format for SLA machines – in addition to several others (you can see a complete list of accepted files on our RFQ page).